General repair shops should look for machines that are capable yet still compact enough to fit in between bays if needed.

Hunter Industry Insights

Finding the Best Tire Changer for Your Shop

Want to make sure you're making the right choice for your business? Read further for important considerations when researching tire changing equipment and how innovative and productive Hunter tire changers can boost your shop's profitability. When you're ready to learn more, contact your local Hunter team for detailed product information, onsite demos and pricing options.

Quick stats

Tire changers

Today, people are keeping their vehicles longer than ever. Tomorrow, electric vehicle tires wear about 20% faster than ICE vehicle tires.

New alloy wheels usually cost between $200 and $500. Proper tire-changing equipment greatly reduces damage risk and subsequent expensive damage claims.

75% of new vehicles are trucks and SUVs. Well-equipped tire changers reduce the time and labor to service these large, heavy assemblies.

Tire Changers

Top 9 things to consider

What defines a good tire changer?

Service Support

Even the most durable tire changer eventually needs service. Make sure the manufacturer supports its products in the field with a team of reliable service representatives.

Training

Does the manufacturer offer training at installation, onsite training, training videos, a thorough operation manual, and anything else necessary to ensure safe and efficient use?

Wheel Protection

This is vital with today's high-performance specialty wheels. All reputable tire changing equipment has wheel protection built into every contact point with the rim or tire.

Robust Design

Tire changers take a lot of abuse. Steel thickness, welds, component size and overall weight are good indicators of a machine's sturdiness and durability.

Diverse Model Offering

Various tire changers are optimized for certain types of tires. The best companies offer appropriate styles of equipment, rather than a “one-size-fits-all” product. HD tires require their own classification of equipment to service.

Torque

Tires today may require more torque to service than previous generations. Pay particular attention to the power choices available, and especially consider 220V options.

Mount Head Type

Leverless tire changers offer superior wheel protection, safety and ease of use for even the most difficult tires. Levered tire changers are fast and familiar for most technicians, but require more effort and pose more damage risk.

Side Shovel Durability

The side shovel arm and mechanism is the most abused component on a tire changer. The size and heft of this system is an easy-to-spot indicator of the tire changer's durability.

Technician safety

Features like a leverless mount head, roller bead breaking, press-assist devices and wheel lifts make the technician’s job safer and easier at the same time.

Shop type

What should different types of shops specifically look for?

General repair shops

Collision

Collision shops are best suited with machines that are easy to use and provide a high level of protection for new alloy wheels.

Automotive dealerships

Dealerships need reliable and durable machines that are suited for today’s newest vehicles with the most challenging fitments.

Tire Dealers

Tire shops need machines built for heavy usage with a multitude of different fitment types. Performance upfit shops need premium equipment to safely and easily service the most radical aftermarket assemblies.

Heavy-Duty

HD assemblies need specialized tire service equipment for the size and weight of HD assemblies, while also providing maximum safety for the technician.

Government & Education

Public service and educational organizations often have a range of vehicles in their fleets, so they may require more than one changer type to cover the total need.

Features of tire changers

What are the most important tire changer features?

Bead loosening

While side shovel bead breakers are very effective, roller bead breaking offers a higher level of wheel and technician safety.

Mount head

The mount/demount head guides beads on and off the wheel, leverless heads are physically easier to use and safer for wheels than traditional heads.

Bead press system

Controlling heavy or stiff beads takes a lot of force, assist devices like press arms allow a single technician to position beads right where they are needed for mounting and demounting.

Blast inflation

The most challenging and time-consuming part of tire service on some fitments can be sealing and seating beads. Built-in blast inflation takes the place of handheld devices, making bead sealing faster and easier for a single technician to perform.

Wheel lift

A wheel lift system is crucial for technician safety. The lift can raise the heaviest assemblies with ease. Additionally, it helps prevent damage to the wheel and eases back strain.

Clamping

Center clamping provides maximum wheel safety and never slips, although it may require adapters for certain wheels. Tabletop clamping is very fast and doesn't require special adapters, but doesn't provide the same level of wheel protection.

Types of tire changers

What are the different types of tire changers?

Automatic

- Same procedures for all tires and wheels

- Maximum safety for operators and wheels

- Consistent service time for all wheel assemblies

- Fastest throughput, allowing techs to do two tasks at once

Leverless

- Reduces wheel damage risk

- Superior for more difficult tires

- Eliminates lever injuries

Conventional

- Easy to use for simple tires

- Many operators are familiar with table-tops

- Increased complexity and effort on harder tires

Clamping style

What are the benefits of each clamping style?

Conventional

Tabletop clamping is very fast, and does not require special adapters, but doesn't provide the same level of wheel protection.

Centering clamp

Center clamping provides maximum wheel safety and never slips. However it may require adapters for certain wheels.

Power

What are the benefits of each power model?

Air models

Offers sufficient power and variable speed without the need for electricity

110v models

Suitable for virtually all locations and feature multi- or variable-speed motors for better control

220v model

Delivers maximum and ample power

Browse tire changers

Powerful tire changers that will meet any shop's needs

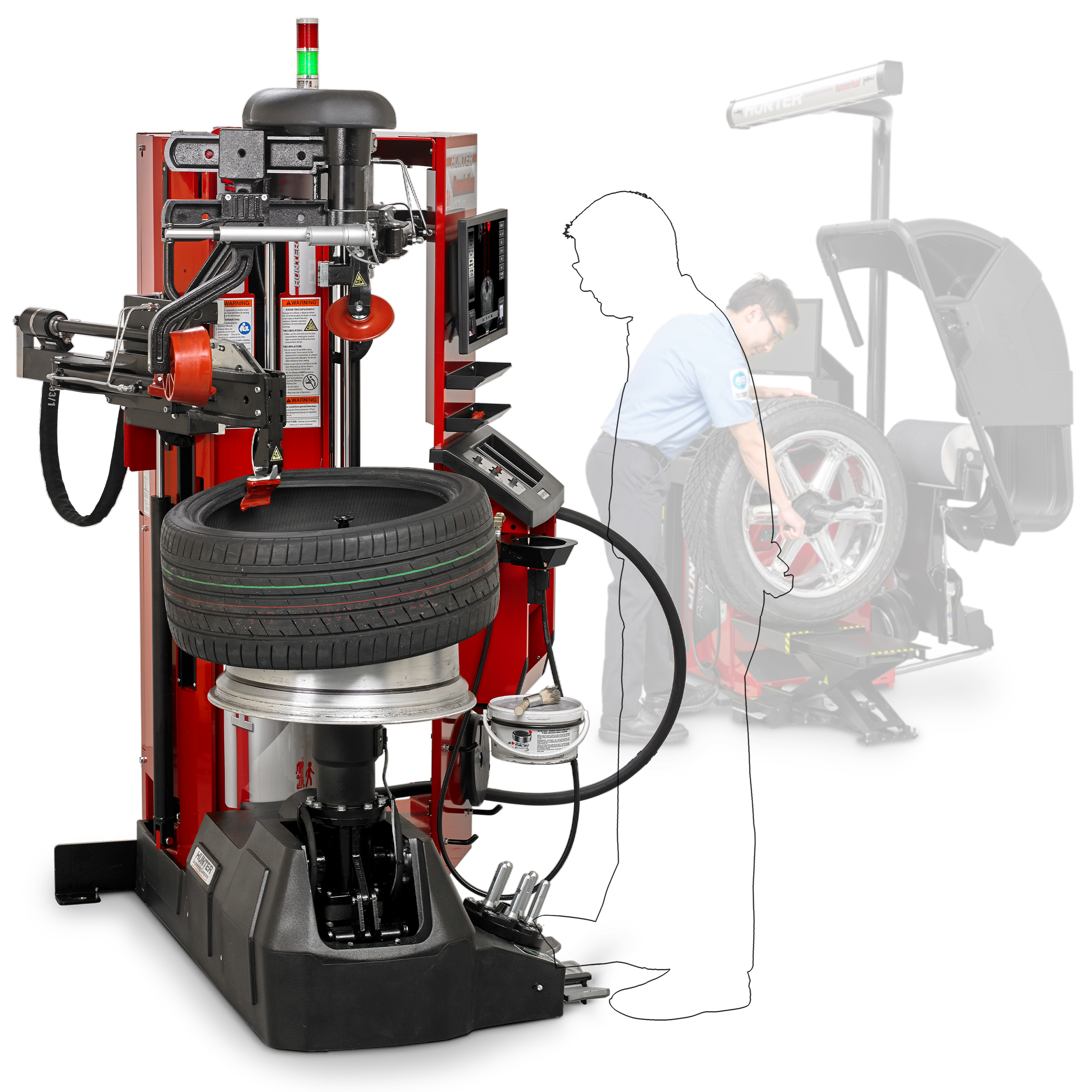

Featured tire changer

Revolution™ Tire Changer

Fully automatic capability makes the Revolution the easiest to use and most award-winning tire machine in the industry.

Learn more

Made in the USA

3-year warranty

Local sales team

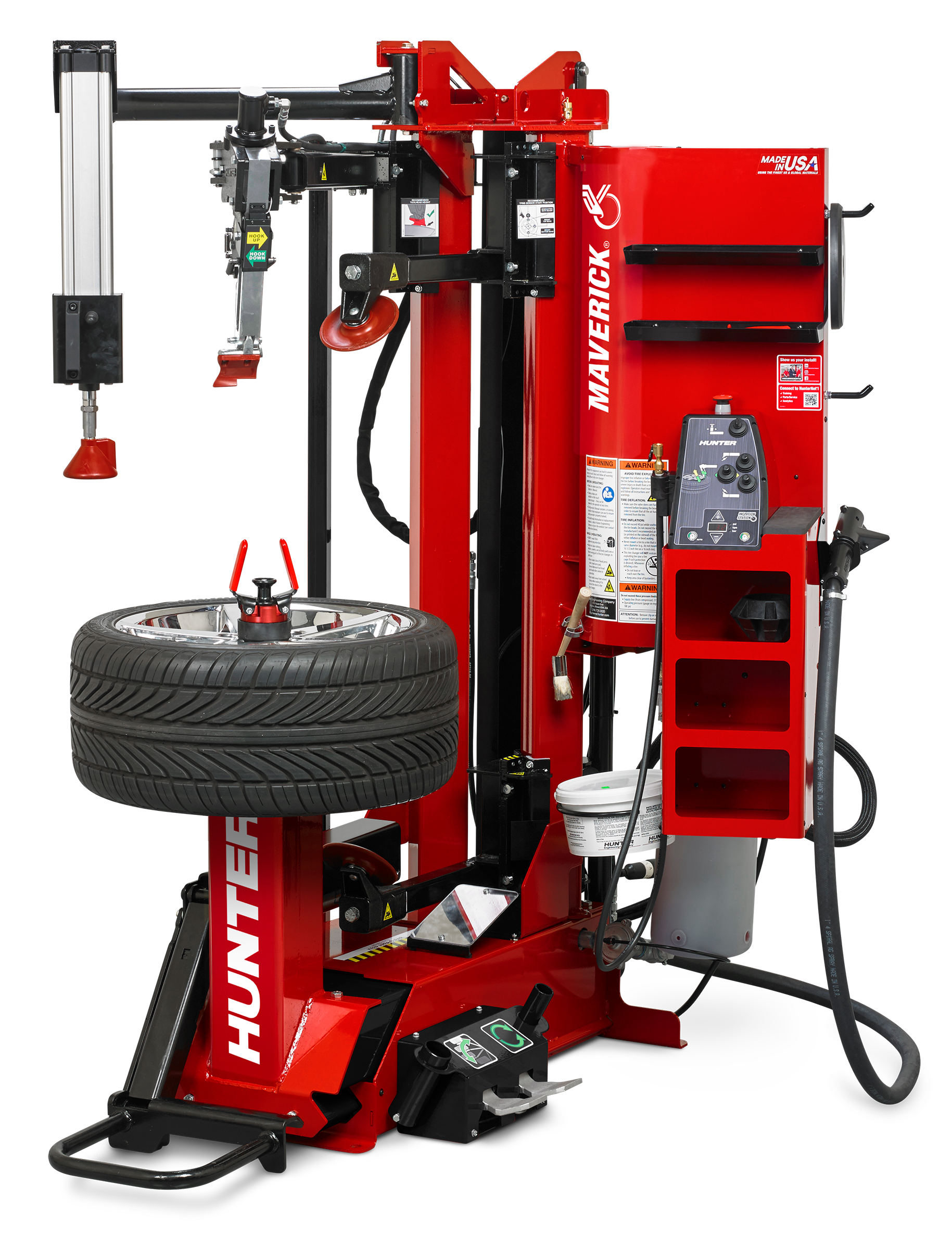

Maverick® Tire Changer

Made in the USA | 3-year warrenty

Technician-focused design provides fully variable hydraulic control and unique features that allow a safe and easy tire-changing process.

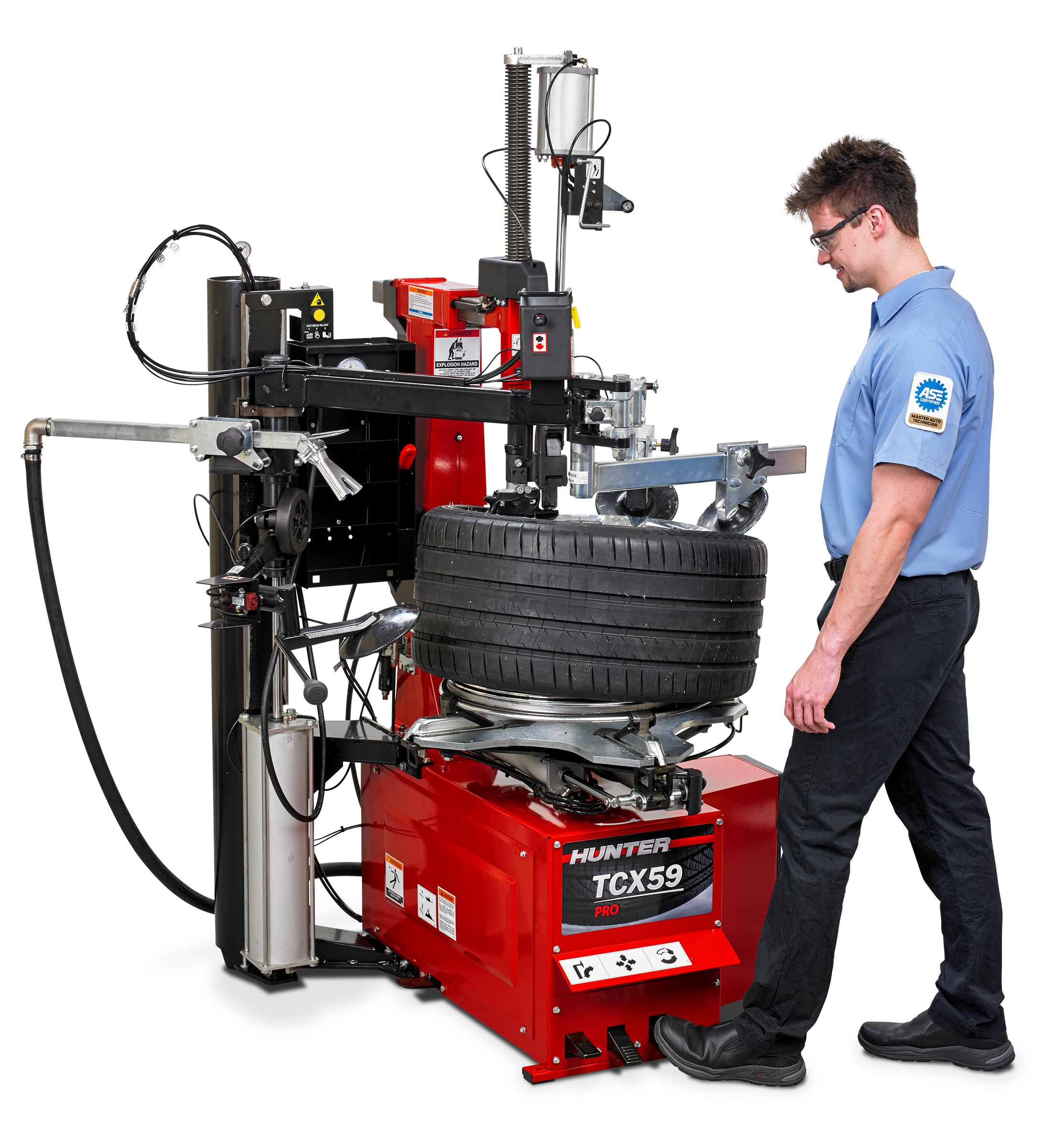

Center-Clamp Tire Changers

Simple operation, superior wheel protection

Table-Top Tire Changers

Powerful & durable

Heavy-Duty Tire Changers

Safe & fast

Wondering about your return on investment?

Easily calculate your expected revenue and quick payoff with the most profitable undercar service equipment.

FAQ